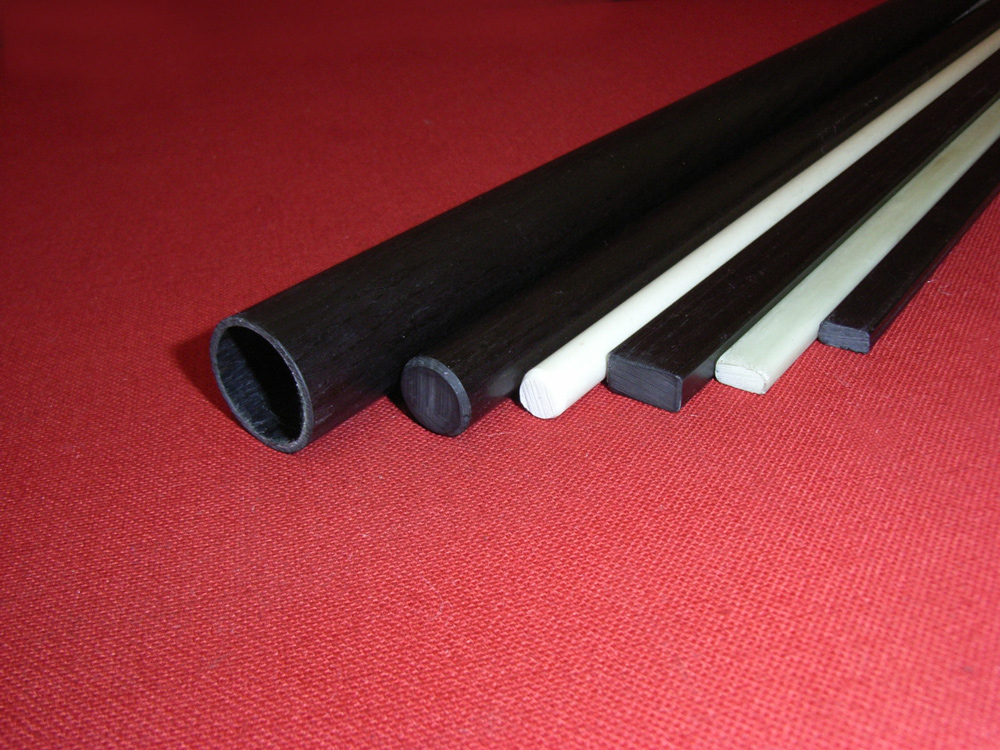

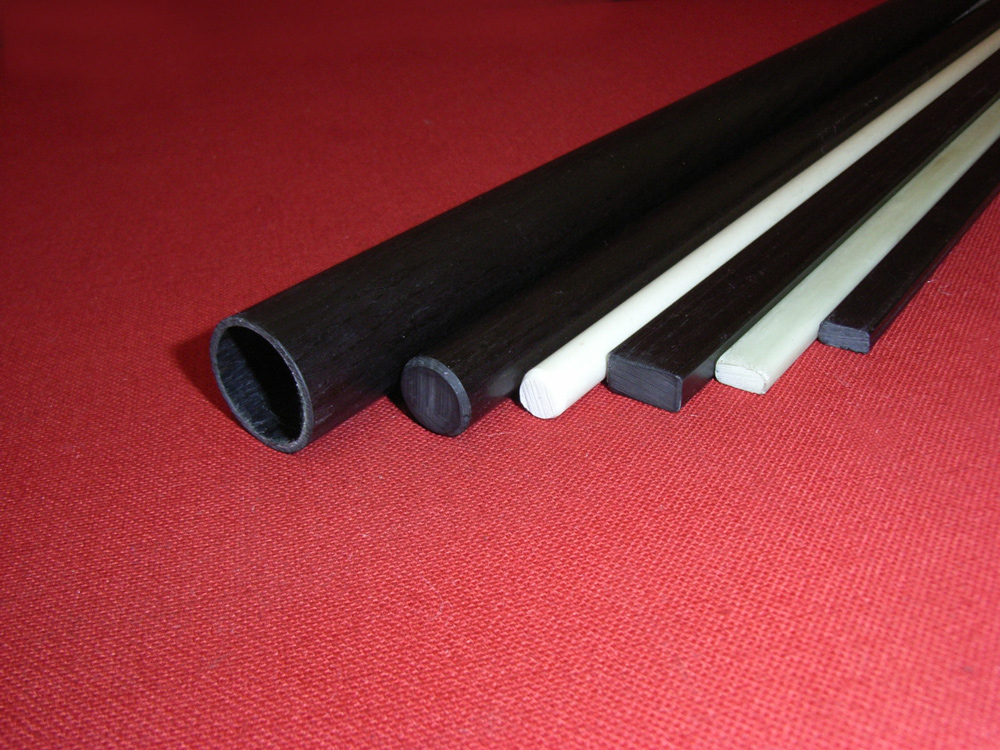

Pultrusions is referred to the process of manufacturing various fiber reinforced and composite structures. This is considered to be one of the most important manufacturing processes. This is a continuous process, which includes pulling out raw fibers from the raw bath or any chamber. This process makes the products durable and offers a distinguished character that makes it important and an efficient solution to be used in industrial, commercial and domestic sectors. There are various structures and tools made out of this, the main reason behind popularity of the products are that the products will last longer and are cost effective.

There are various uses of pultruded products in everyday life. These are few of the common uses of pultrusions is manufacturing various materials and the reasons that make them successful installation:

- LadderRails:

Ladder rails are basically used while working in buildings and while trimming trees. The traditional material used in making ladder rails is aluminum. But these are corrosive and highly conductive. An alternative to this is the use of pultruded fiberglass as these are resistant to corrosion and non-conductors of electricity. This proves to be a better option to work and is successful in saving lives of hundreds working on them. These products do not react with the natural elements like UV rays and etc.

- Window And Door Frames:

It is advisable to use window frames and door frames made of pultruded fiberglass products. The main reason that works behind the idea is that they are not subjected to thermal expansion. The continuous expansion and contraction of the panels are not desirable. Traditional alternatives like Vinyl window frames or aluminum door frames are subjected to thermal expansion and contraction. These are therefore not a feasible option. Window lineal made of pultruded fiberglass can be installed easily and light as well. Moreover, the pultruded materials are not subjected to any kind of wear and tear.

Tool Handles:

Pultruded fiberglass tool handles exhibit various characteristics and these are extremely useful for making tool handles. It is easy to be manufactured and can be made of any vibrant color which increases the visibility of the product as well. The installation of these does not give rise to scraps, lightweight, and durable are other characters that make it a more feasible option. There is no risk of dents while shipping, installation and use of the products. The most important characteristic is that they are non-conductor of heat and electricity.

Apart from this pultrusions is used to manufacture various structures to be installed at power plants, off- shore drilling industries, cooling tower and composite armor structures. These products are easy to manufacture and are efficient to be used in any environment. Another distinctive quality is that they are transparent to radio waves and signals and, therefore, can be used successfully in industrial or household environment.